If using high quality equipment kept in good condition and if such equipment is used properly maintaining all health and safety rules, oxy-fuel cutting and heating equipment is safe to handle. There is no substitue for proper training, safety procedures and adequate caution among those that operate oxy-fuel equipment. The right torch, nozzle and stable source of gas as well as their professional handling is essential but still may not be sufficient. Daily practice shows that backfire and flashbacks not only may happen but happen quite frequently. Extra hardware in the form of reliably working flashback arrestors provides an additional safety barrier protecting the cutting / welding operator and surrounding property against health and safety risks and material damages.

Backflow is a dangerous situation whereby oxygen is pushed in to the flammable gas hose (or vice versa) creating a highly flammable / explosive gas mixture inside the flexible hoses. A damaged injector or mixed or more often clogged or blocked welding tip or damaged cutting nozzles can also cause a change of inner pressure conditions in the system resulting in backflow. Another case is where the reverse flow of gas occurs when one cylinder runs out during operation, creating an imbalance of pressure in the system. The non - return valve units - both in check valves and / or flashback arrestors are the only devise able to minimize this serious risk.

A flashback is momentary or sustained retrogression of the flame upstream of the mixer, usually in the torch or hoses. This is potentially dangerous situation, partially if the flame reaches the hoses, where an explosion will occur, causing a rupture or separation of the hose.

Sustained backfire is the continuous burning of the flame back inside the torch, usually at the mixer or injector. Flames can also travel further upstream and in extreme cases can reach the regulator and gas cylinders. Sustained backfires are often accompanied by a hissing or squealing sound and / or a smoky, sharp pointed flame. The user should immediately close all torch valves to avoid damage or injury. If sustained backfire continuous to burn without closing torch valves, severe damage to torch, as well as increased risk of fire, would result.

Device which prevents the passage of gas in the opposite direction to normal flow. NRV is an essential unit preventing gas back flow.

Unit designed to extinguish fire and stop buring propagation by high heat dissipation when passing internal FBA sintered filter. A negative feature of every sintered flame arresting filter is flow restriction and pressure drop which gets worse when the filter gas clogged by gas impurities or burning products.

Device which stops gas flow if the surrounding or internal temperature reaches specific level. The flow is stopped by a spring valve actuated by the melting of thermal fuse and is not resettable.

Device which stops the gas flow in case of reverse pressure wave travelling upstream through the system towards FBA. The pressure sensitive valve on a GCE FBA is resettable.

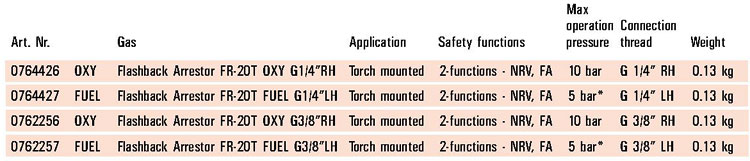

FR20 is robust but lightweight torch flashback arrestor specially designed for torch fitting. Its all brass design and high grade soft sealing elements makes FR20 fully compatible with all common technical gases.

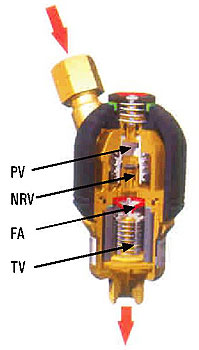

The unit incorporates the following features

![]() FA SINTERED FLASH ARRESTOR element to quench a flashback.

FA SINTERED FLASH ARRESTOR element to quench a flashback.

![]() NV NON-RETURN VALVE to prevent reverse flow of gases.

NV NON-RETURN VALVE to prevent reverse flow of gases.

High capacity sintered metal filter prevents foreign matter entering the unit but guarantees capacity enough for all manual and medium duty machine cutting applications. All FR20 flashback arrestors conform to EN 730

The FR34 flashback arrestors are basic models of 3 function FBA designed to be mounted on the regulator side. Flow capacity of FR34 is sufficient for a whole range of manual cutting or welding applications and even for basic machine cutting up to 200mm. These arrestors fully comply with EN730 and ISO5175. FR34 offers three safety functions.

![]() FA Sintered flame arresting element.

FA Sintered flame arresting element.

![]() NV Non return valve to prevent reverse flow of gases.

NV Non return valve to prevent reverse flow of gases.

![]() TV thermal trip device, activated by heat to permanently cut off gas supply.

TV thermal trip device, activated by heat to permanently cut off gas supply.